Specifications of TUPRO

Design TUPRO

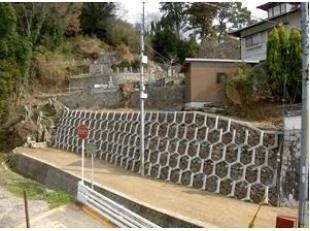

TUPRO (TUrap PROgresif) is a retaining wall constructed with a stone arrangement and branching concrete blocks as binders.

Three construction points include:

- Branching concrete block design.

- Interlocking concrete block arrangement.

- The main material used is natural stone (andesite type) arranged using the Japanese "Ishizumi Method," which creates a stable structure that is not easily dislodged.

Main Material Using Natural Stone

With the majority of the material being stone, it is not only environmentally friendly but also strong. In addition to being sturdy and robust, it is also good for the environment as it can create new habitats for animals and other plants. The arranged stones have gaps and pores that will distribute groundwater, thus maintaining the balance of active and passive pressure.

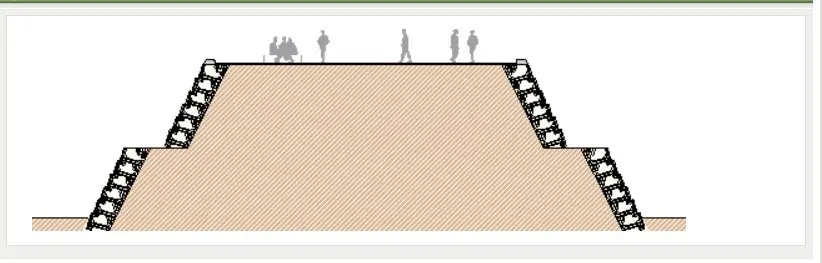

Application of TUPRO

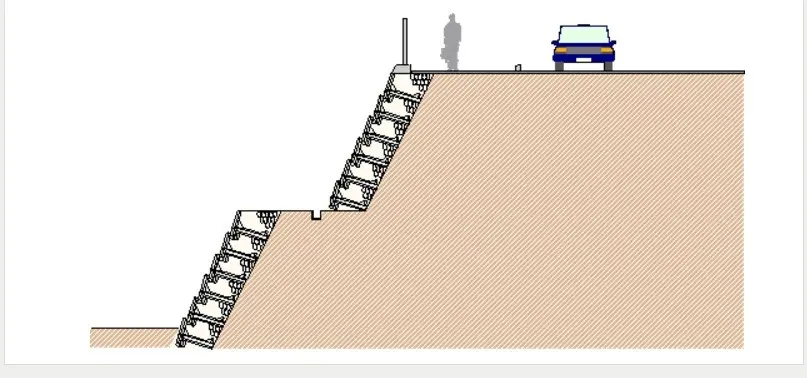

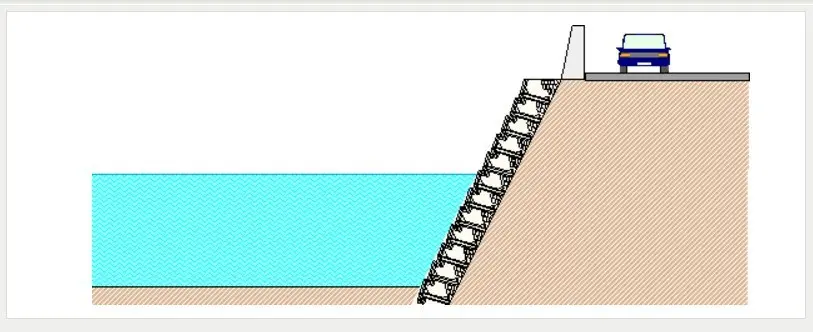

TUPRO is applied with a slope installation of 1:0.3 to 1:0.5

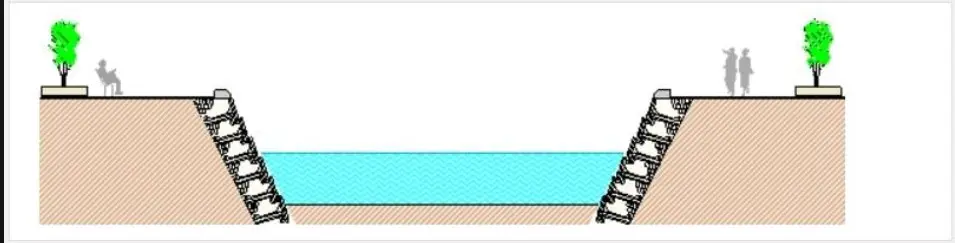

(1) Riverbank, River Cliff

(3) Hills, Mountain Slopes, Slopes on the Motorway

(2) Dam Cliff

(4) Fill Soil

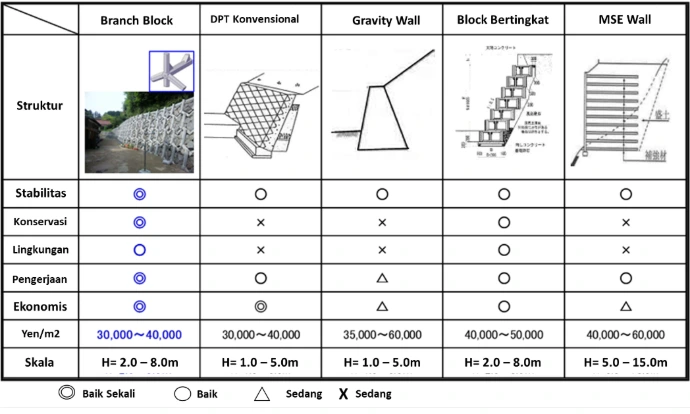

Comparison of TUPRO with Other Methods

Besides Tupro, other methods generally use concrete. Its strength depends on how large, how deep, and how much cost is incurred.

This method will hold up well if the following conditions are met.

1. THERE IS NO CHANGE in the shape and position of the pile.

2. THERE IS NO CHANGE in pressure/load from above, the sides and the back.

If one of them changes due to rain and other factors, it may become damaged because it is not flexible enough to adapt to those changes..

→ However, in certain conditions, we may still use this method.

Comparison of TUPRO with Other Methods

Limitations of TUPRO

Ideal conditions for TUPRO installation

- Comparison of angles level 1:0.3 ~ 0.5 (range 60 to 70 degrees).

- The ideal installation height of Tupro is from 2 metres to 8 metres; if it exceeds 8 metres, terracing should be used.

- TUPRO can be applied to various types of soil including expansive soil, but the soil bearing capacity needs to be considered.

- If the load-bearing analysis indicates that there is a need for soil improvement and/or structural reinforcement using minipiles and similar methods.

Production Process of TUPRO Block Until Installation

01

Production of TUPRO Block

02

Delivery from Batching Plant

03

Installation of TUPRO

04

Completion Stage

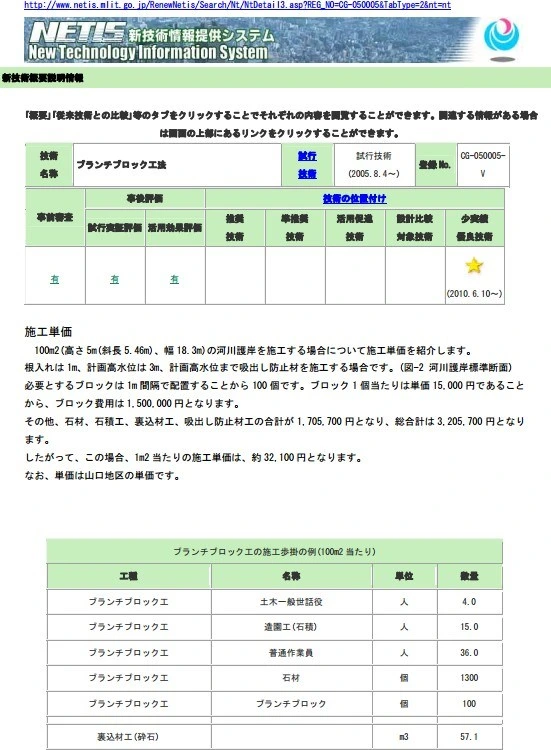

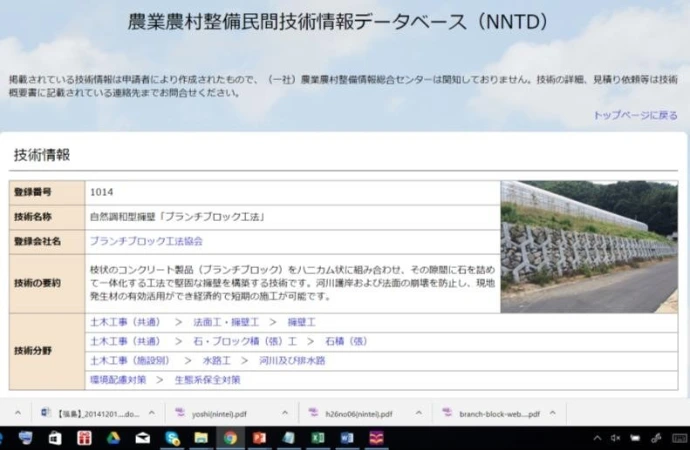

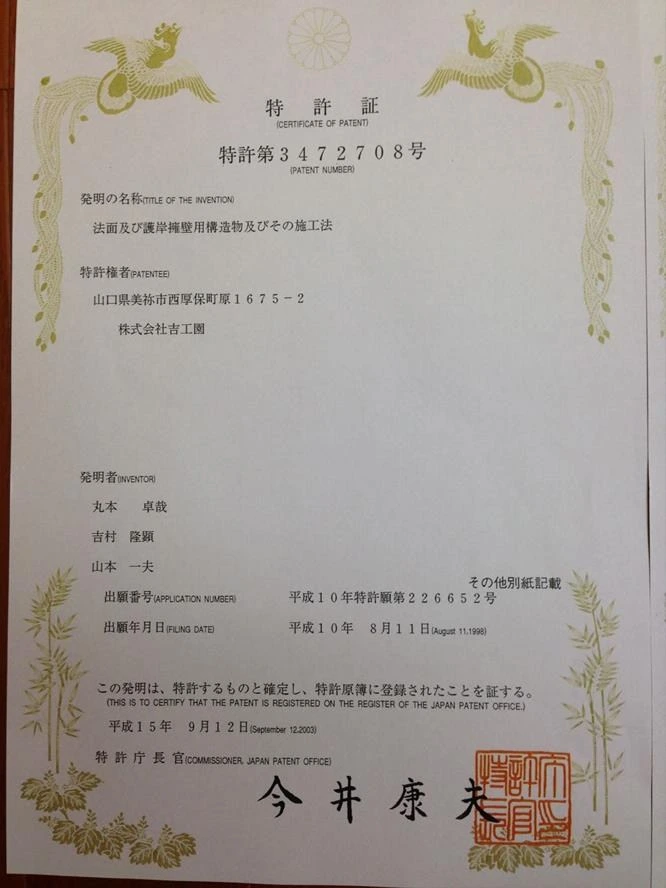

Certification in Japan

NETIS No. CG -050005-V (New Technology Information System/ Ministry of Land, Infrastructure, Transport and Tourism of Japan).

ARIC No. 1014 (Agriculture and Rural Development Information Center/ Ministry of Agriculture, Forestry and Fisheries of Japan).

Patent No. 3472708

(Patent Office of Japan)

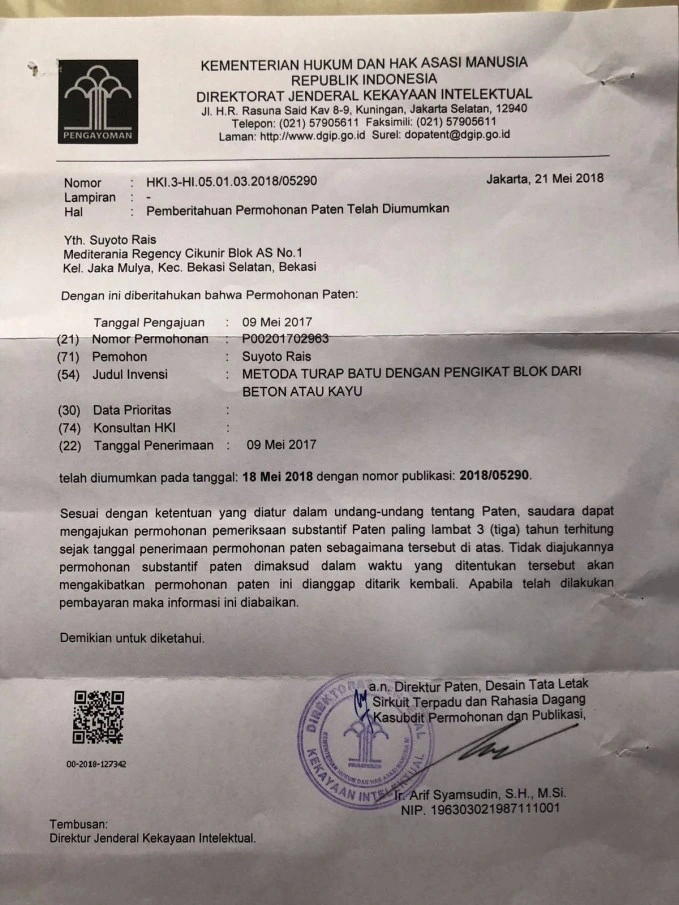

Registration of Trademark and Patent Rights in Indonesia

Trademark Registration

(3 March 2017)

Patent Registration Process

(9 May 2017) and was published on 21 May 2018.

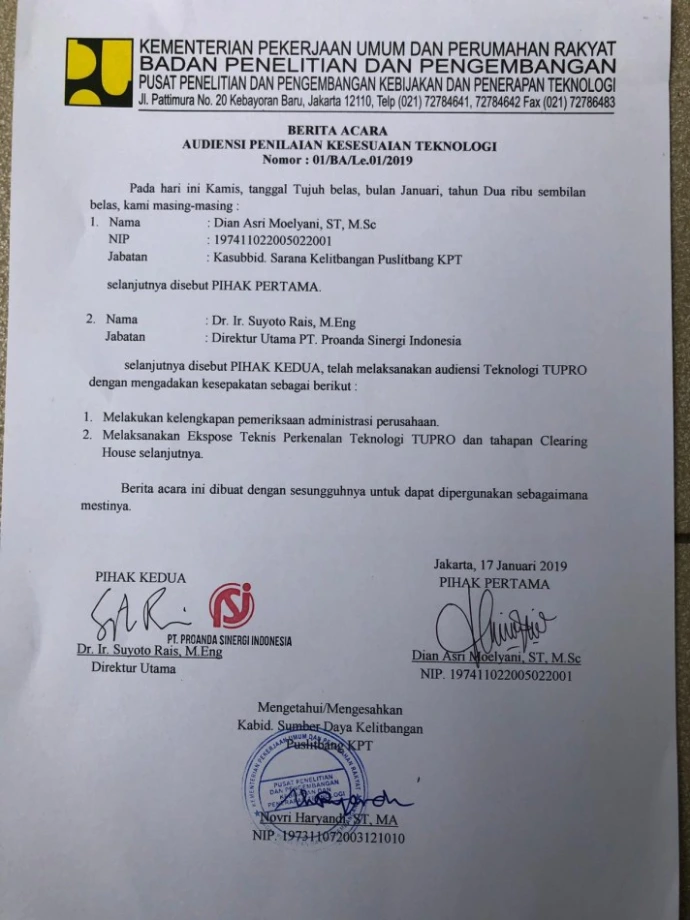

Consultation with PUPR and start the process

entering E-catalogue.

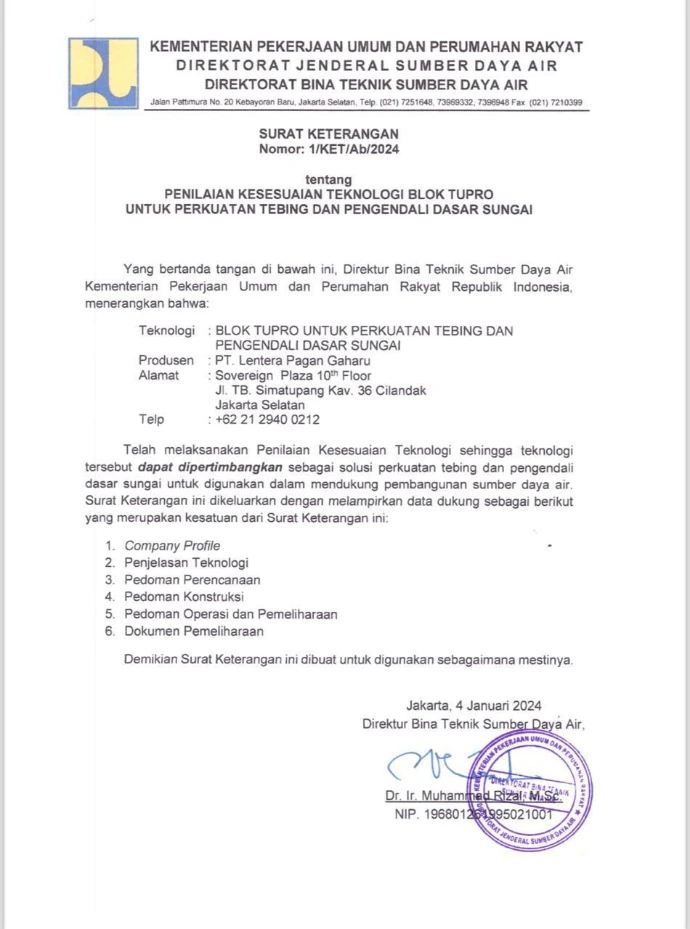

Recommendation

Ministry

PUPR

On 4 January 2024, Tupro received a letter of recommendation signed by the Director of Water Resource Engineering at the Ministry of Public Works and Public Housing of the Republic of Indonesia.

Installation of TUPRO in Japan

Before Installation

After Installation (February 2003)

After 6 Years (2009)

After the heavy flood in July 2009, TUPRO was not damaged at all. Landslides occurred in other areas where TUPRO was not installed.

Now it remains strong even covered by naturally growing green plants.

Application of TUPRO in Japan

Used in many places that are prone to landslides, such as riverbanks and cliffs.